WHAT WE DO

Why choose

La Cibek die casting

La Cibek die casting was founded in 1968 by Cilio Zani, father of Marina Zani, the current director. It is characterized by the continuity and the strength of its values, such as its consolidated partnerships with customers and suppliers (especially the die casting and trimming tool suppliers, the surface finishing, machining, painting and customized packaging suppliers) the involvement and training of its employees, and the attention paid to the environmental sustainability of its die-casting process.

FROM THEORETICAL DIE-CASTING PARAMETERS TO ACTUAL PARAMETERS

The design and offer documentation in English or German further enhance the services offered by the company, which is now present in foreign markets with more than 50% of its turnover, especially in Germany and Switzerland.

MOULDS

Attentive to customer’s needs, La Cibek die casting uses advanced technologies to maximize the start-up time of a new project.

Manufacturing resources

The quality of mould construction is ensured with the help of a network of long-term specialized partners.

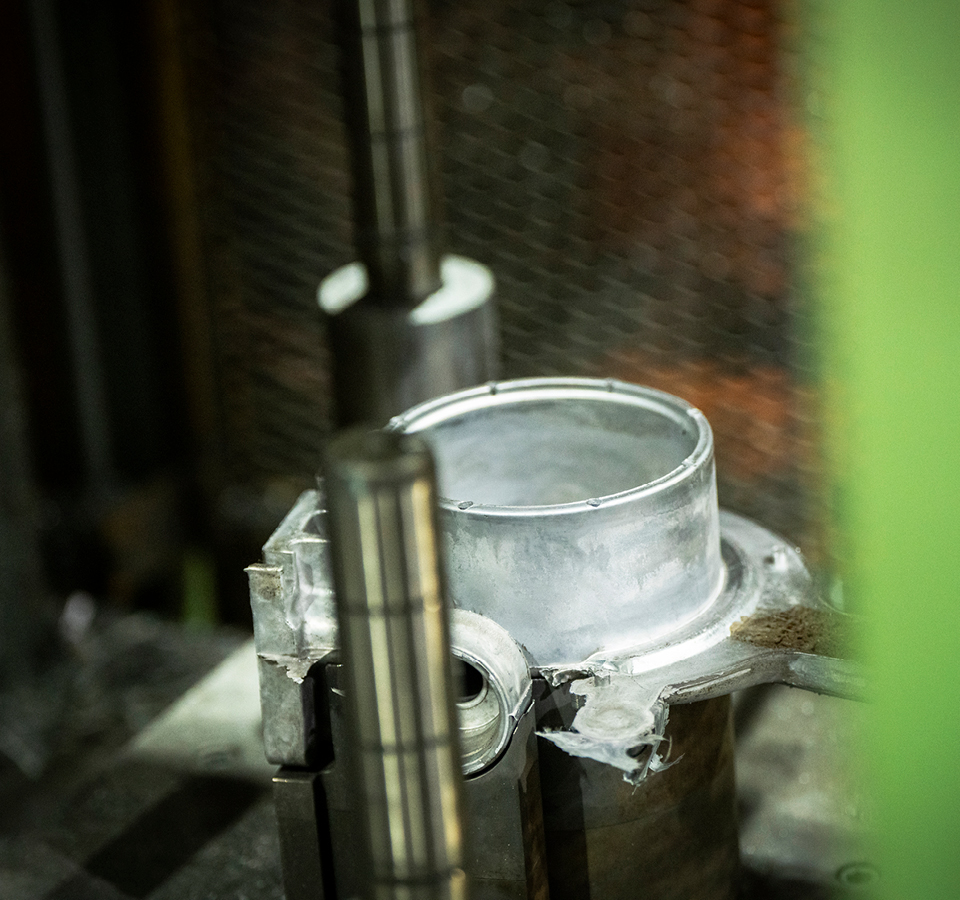

ALUMINIUM

DIE CASTING

La Cibek die casting produces high quality die castings in Aluminium, Zinc and special alloys.

FINISHING

Items complete with any other processing subsequent to casting: trimming, deburring, protective and surface treatments.

– DISTINCTIVE ELEMENTS –

Production, the distinctive elements

- The production of die castings in medium/small batches, but with high quality;

- The supply of Aluminium and Zamak die castings complete with all post-casting processing: shearing, deburring, surface treatments (sandblasting, tumbling, polishing);

- The manufacture of Aluminium and Zamak die castings with iron, stainless steel or brass inserts incorporated in the casting;

- The production of high quality tooling combined with low mould costs;

- The use of special alloys (e.g. Zamak 27 ZA27C2 – UNI 9408, Magsimal59 Rheinfelden, Silafont Rheinfelden, Piral UNI 6253-58);

What La Cibek die casting offers

- The execution of protective treatments (painting, nickel-plating, chrome-plating) and the provision of accurate packaging;

- The execution of machining operations (from simple threads to more complex machining operations);

- X-ray and 3D inspection with a HEXAGON Mistrala 5-axis system (3x CMM) with accuracy level 3µ+4µxL/1000;

- The offer of a “prompt delivery” service for parts for which an authorized stock lot has been agreed in advance with the customer.

– CONTACT US –