Aluminium Die Casting

LA CIBEK DIE CASTING - Italy

Production Die Casting facilities

|

|

|

|

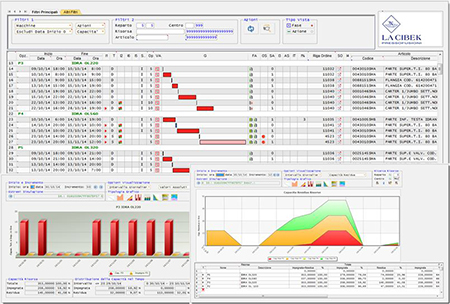

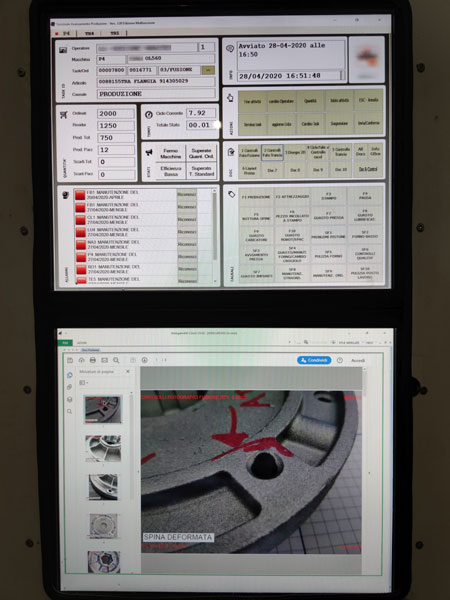

Management and Control of Die Casting facilities

The adoption of recent production technologies and the use of a fully integrated information system with the production processes and with the module of production planning, guarantees a constant control of all the stages of processing, maintaining a constant level of conformity of Die Casting products.

Furthermore, repetitive 3D dimensional controls by 5 axis HEXAGON system and controls of Die Casting homogeneity performed by our X-ray system, guarantee a consistent quality on each lot that at the end of working processes, will be packed in compliance with customer packaging specifications.

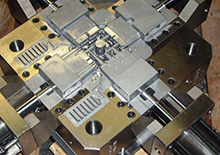

The company’s production systems allow to realize Aluminum and Zinc Die castings, weighing from a few grams up to 6 kg. These products are intended for different sectors such as: Hydraulic, Electrical, Electronics, OIL&GAS, Agriculture, Pneumatics, Industrial automation and cleaning machines, Professional appliances, Measuring Instruments and LPG equipment for automobiles.

|

|

For manufacturing Aluminum and Zama Die-Casting components, Company production facilities include the following Press:

Presses

- Nr. 2 IDRA OL 200 tons Die Casting Machine;

- Nr. 1 IDRA OL 300 tons Die Casting Machine;

- Nr. 1 IDRA OL 400 tons Die Casting Machine;

- Nr. 1 IDRA OL 650 tons Die Casting Machine;

Trimming Presses

- Nr. 1 DIESSE 20 tons Trimming Machine;

- Nr. 1 DIESSE 25 tons Trimming Machine;

Our foundry works on 2 shifts.

|

|

|

|

©2023 LA CIBEK SRL -

Pressofusione Alluminio e Zama - Via per Ospitaletto, 151 - 25046

Cazzago San Martino (Brescia) Italy

Tel. +39 030 7759918 - E-Mail:

[email protected] - Capitale

Sociale 100.000 Euro i.v. Cod. Fiscale e P.IVA 01689590980

R.E.A. di

BS n. 0340568 - Reg. Imprese di Brescia 01689590980

Principali aree

Italia: Reggio Emilia, Modena, Bologna, Milano, Pordenone, Roma, Napoli

- Aree estere: Stoccarda, Monaco - Estero:

La Cibek

Aluminiumdruckguss